This is how I did my

right side front brake conversion. Well, in my case it's a left brake

conversion because I swapped my forks so the calipers are in the rear.

First thing's first. Buy a left side caliper on fleabay, then immediately

order a new piston because you'll probably need one. The one that came with

mine was OK but had the usual pitting and corrosion under the exposed part

under the seal. I ordered mine from HVC, he has new stainless pistons for 25

bucks, can't go wrong. Then order some new brake pads. I also ordered a

couple of new bleeders while I was at it.

Next, take it apart and clean and degrease it. This is a good time to

inspect it before you proceed.

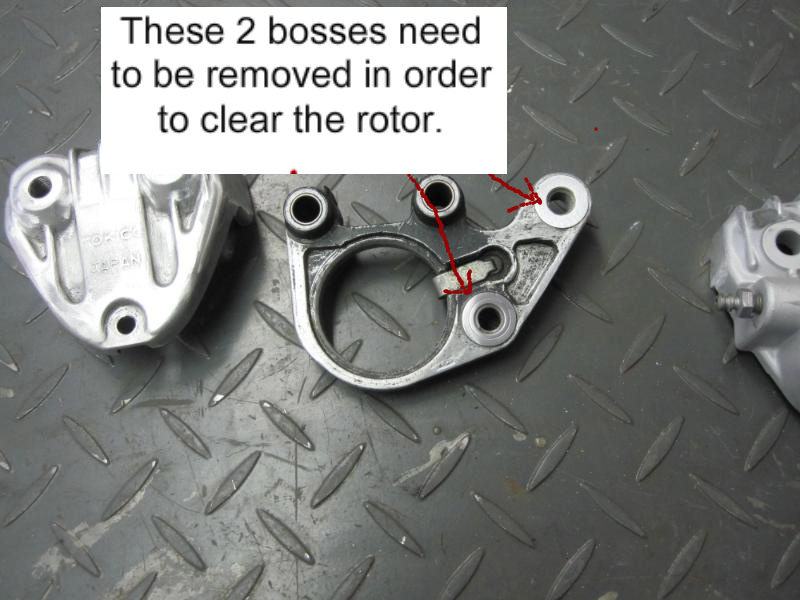

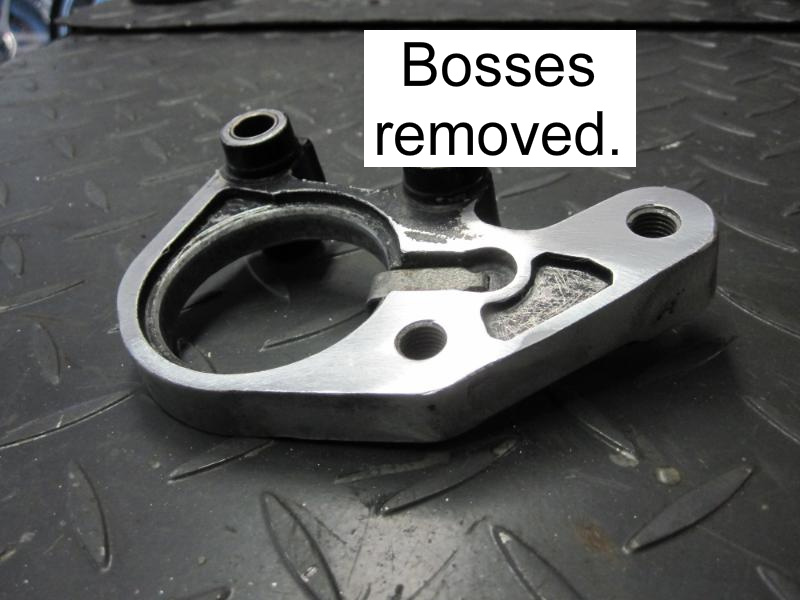

The first thing you'll

need to do is remove the 2 bosses on the bracket. These sit against the

forks when mounted on the left side. They need to be removed in order to

have enough clearance for the rotor. You can use a grinder for this. They

don't need to be machined because this will now be the open end that faces

inside and won't sit up against anything now.

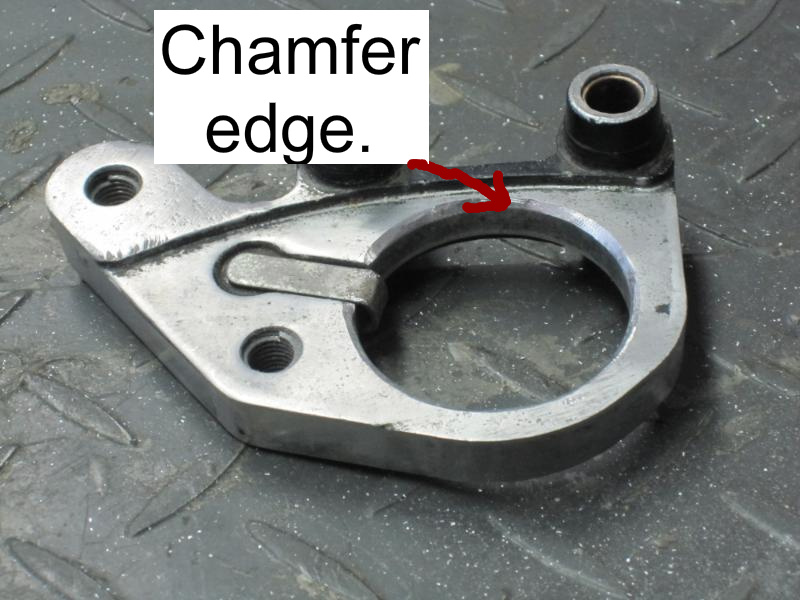

On the other side, I

chamfered the edge. This is done for clearance of the rubber piston boot. It

now mounts from this side. After I cleaned up this edge, I decided to glass

bead everything. I kept the old bleeder in place and put a bolt in the brake

line inlet to keep the glass beads out. When I was done, I chased the

threads and blew everything out with compressed air and thoroughly rinsed

everything out. More compressed air, then let it all air dry for a while in

the sun.

Since this is now the

side that bolts up to the forks, there needs to be material built up around

the lower bolt hole. I did the obvious and just used a washer. I used a 3/8"

washer that was the correct thickness to bring it to the same level as the

raised area around the top hole. Don't ask me what the thickness is, I found

one that matched up perfectly. Just run a steel straightedge across the two

to get them even. I then used a quick setting 2 part epoxy to attach the

washer and held it in place with a bolt hand tightened only. The washer is

held in place on the bike by the mounting bolt so the washer being attached

with epoxy isn't meant to be structural, it's just to keep it in place. When

it's painted the washer will look (and function) just like the original

bosses on the other side.

All that's left is paint.

I used VHT high temp satin finish roll cage paint.

Once I get the new piston

and bleeders, all that's left is the brake lines and bleeding the brakes.