Cylinders

Interesting how the first models of all triples have high power spec cylinders! The numbers here are not accurate but, H1's approx the first 6,000 had the bridged port cyls, The S2 had high power for around 6,200 motors, the S1 250 had high power for the first 5,000 units and the H2 had high power for around the first 6,500 units - A sales ploy ? The only Triple that didn't start out with more power is the S3. - Rick Brett

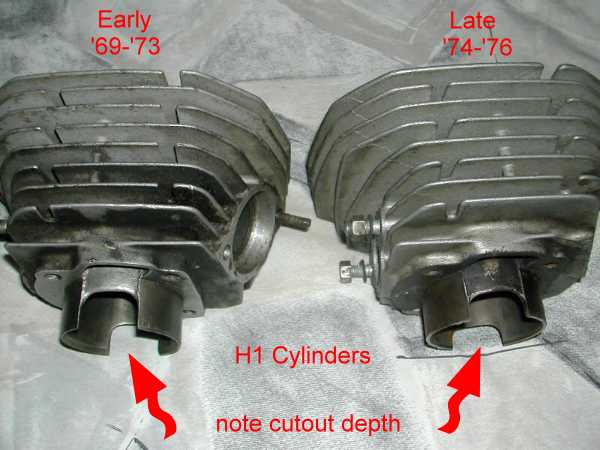

H1 Cylinders

Cylinder Base Dimensions (pdf)

Early H1 exhaust mount studs were stepped in size

(8mm at cyl to 6mm at mount). Late H1 studs were 8mm.

The center to center spacing of studs is wider on the late cylinders by about

2mm.

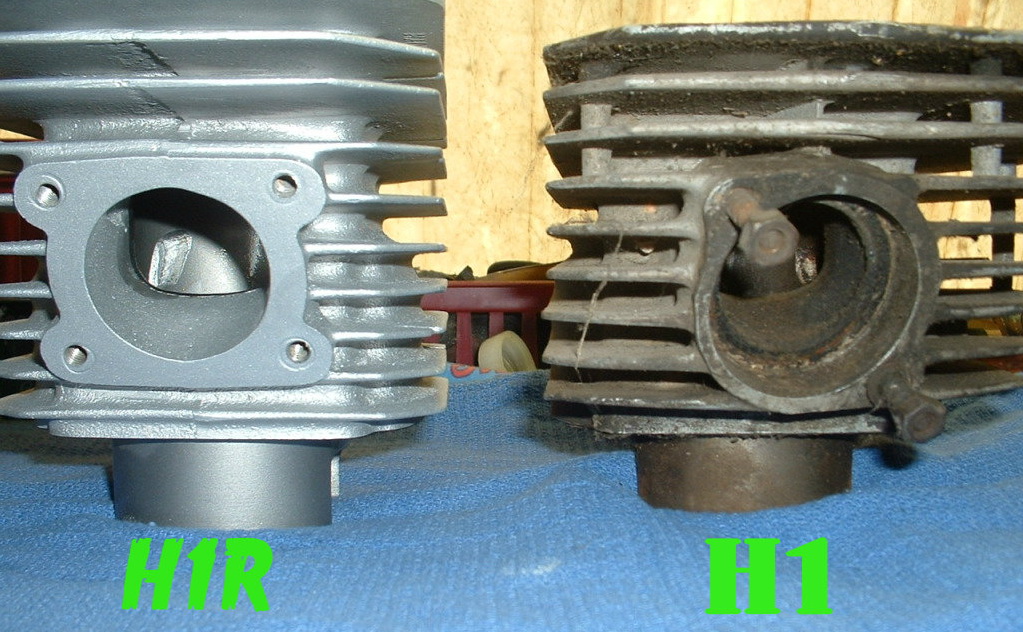

H2 Cylinders

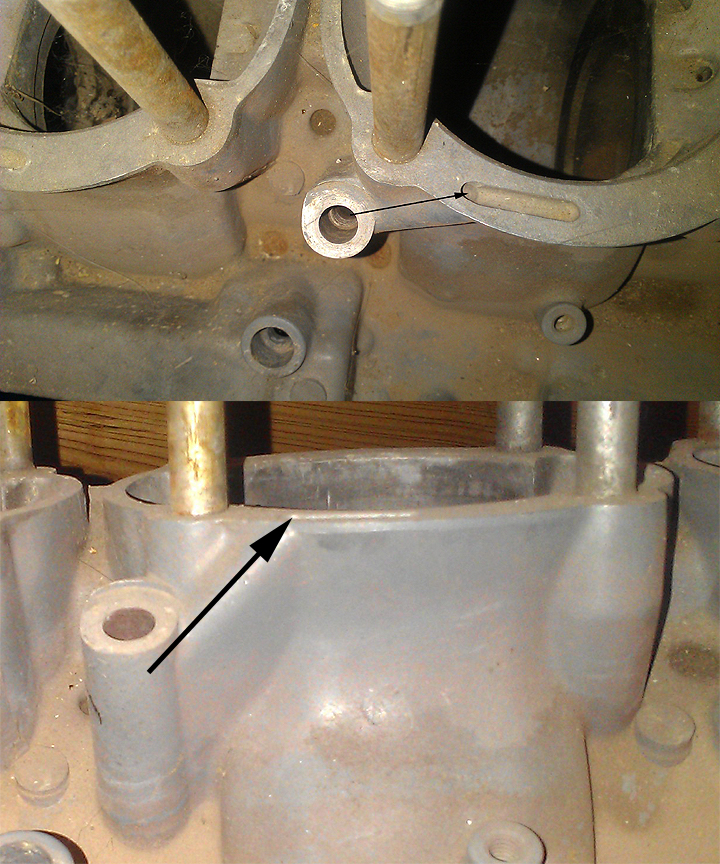

The cylinder

with the square cut out is a 1971 cylinder ONLY, it is totally unique and no

other cylinder can be cut to match the porting as the liner and casting sit in a

totally different position to all others. The 1972 and 1973 also had 2 more

porting specs, the 1974 and 1975 are also a different spec, so there are FOUR

cylinder port specs.

The pistons for the 1971 & 1972 models have a higher cut out in the skirt. -

Rick Brett

Note: TP1, 2, etc are casting mold identifiers and have nothing to do with port or cylinder design.

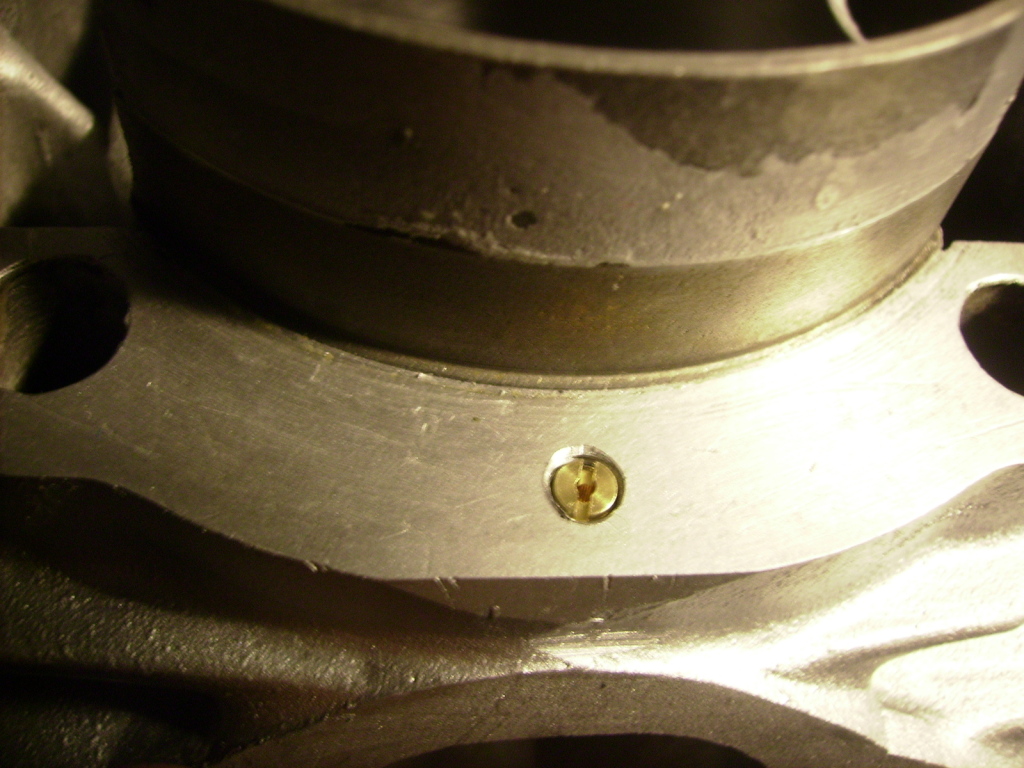

The H2B/C

cylinders are not fitted with oil "jets", nor are the cases drilled. To

fit late cylinders on early cases you can tap the

oil hole to 5 X.08,

cut the end off of a #30 pilot

jet, and install only the threaded portion of the jet in the hole. Don't

drill all the way

through when getting the hole ready to tap, so there is no way the jet can end

up stuck to your piston. And use high strength loctite. The #30 pilot jet is about

the same size hole as the pressed in jet in the early cylinders.

- Bryan H.

S1 Cylinders

Late S1

Early S1

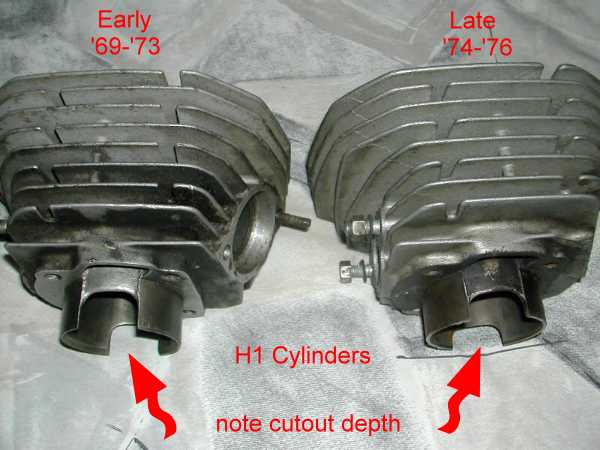

H2R Cylinders

KR 750 Cylinders

s