Inlet Mods - jyrg

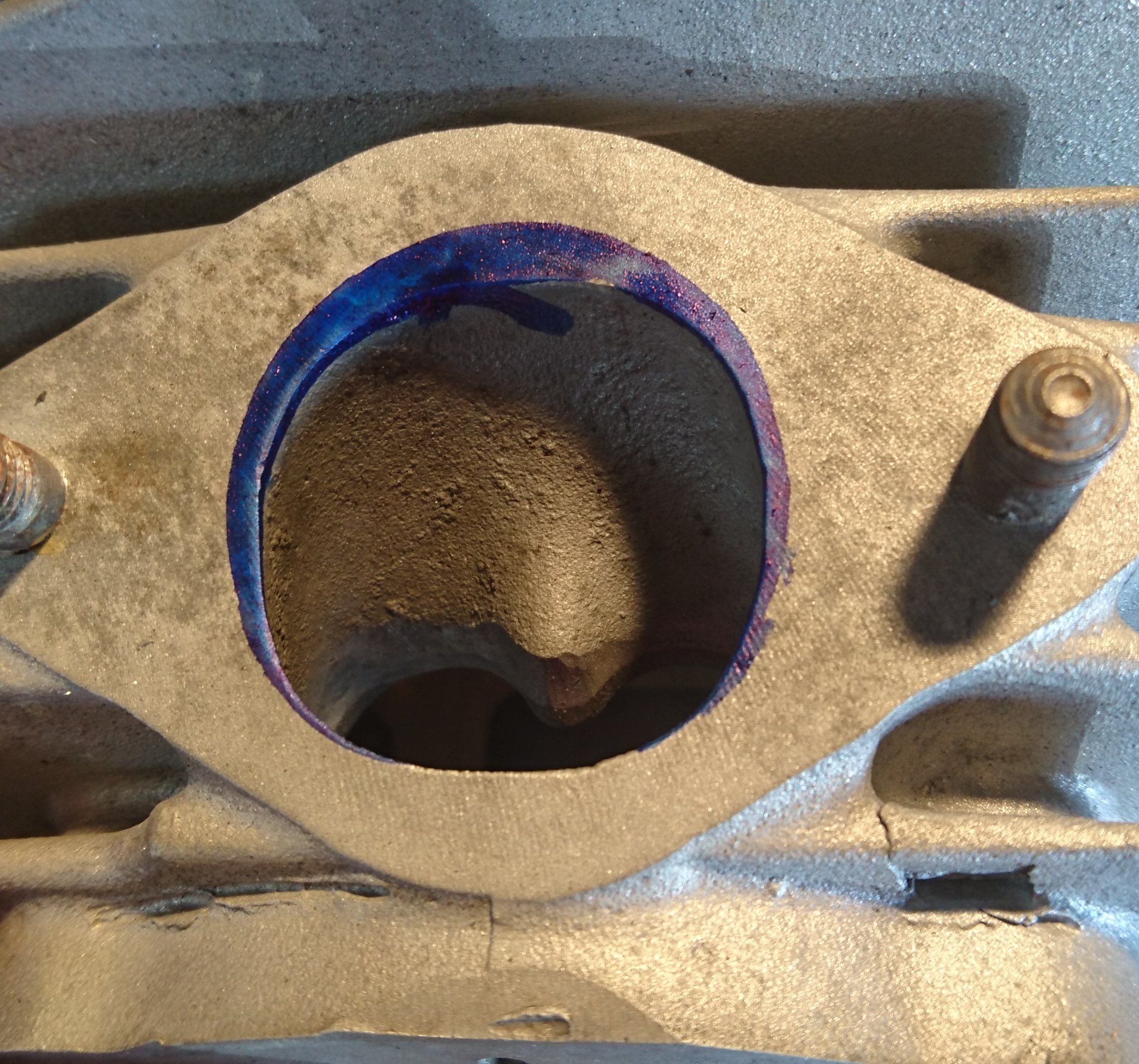

This photo shows what needs to be done with the inlet widow to make the bigger

rubber inlet to fit with a good alignment to casting (and that is important).

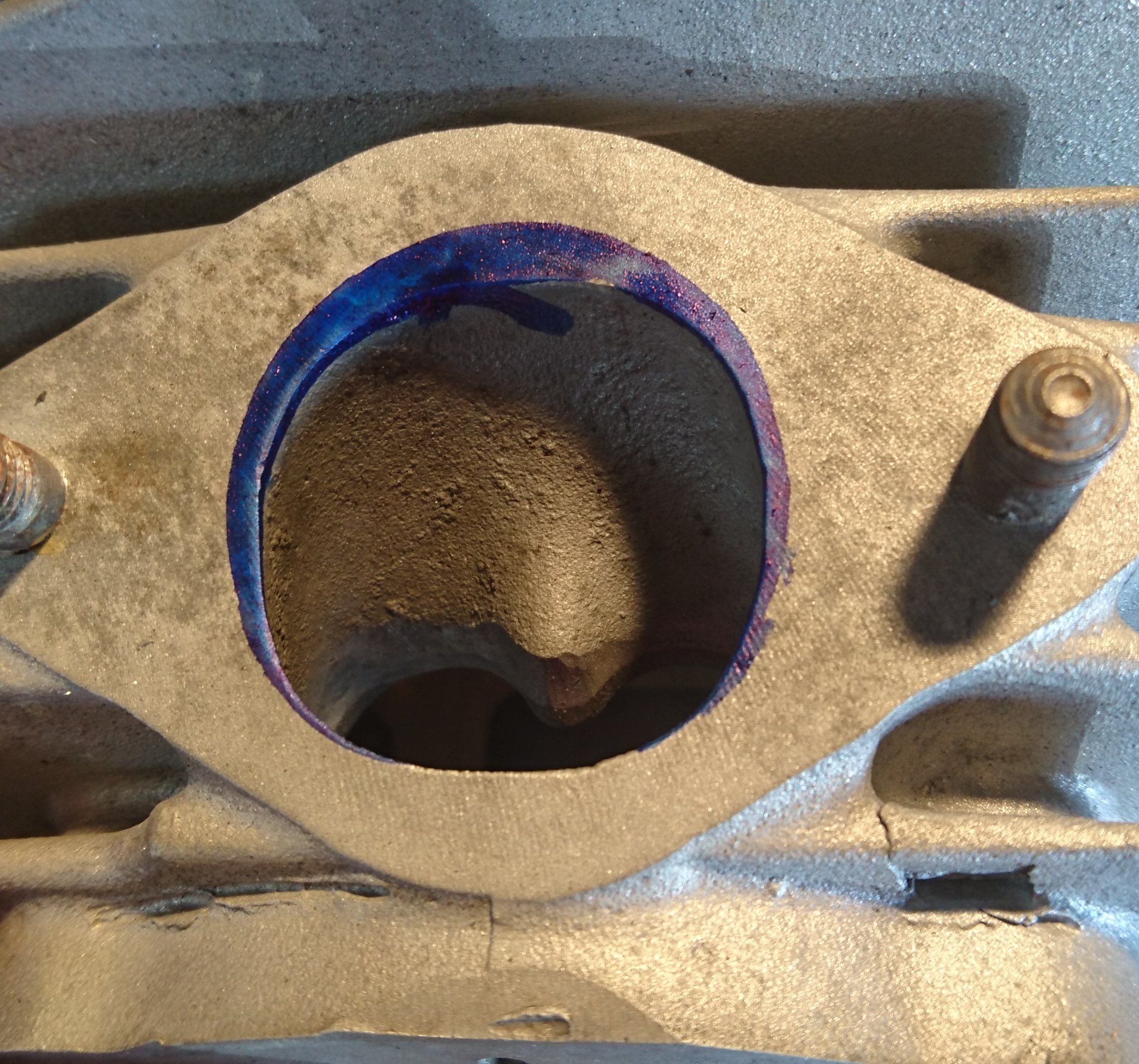

This picture shows a modified piston that has exact same curvature as inlet bore

window. This way, you get a tiny bit better pick-up signal to those big carbs,

which is kind of necessary for low, low rpm. The signal gets more "digital",

than the stock more "analog" signal. A more abrupt signal, good for sucking up

gas from carb bowl at very low revs.

I leave the inlet port stock. But using a 80 grit sanding roll for correct surface roughness is good.... Polished is BAD.

I suggest NOT flatten the inlet window itself. It wears the piston skirt, AND the distance from bottom of inlet window to the transfer cut-out rear part, decreases. I don't want any to experience what I did on 73mm bore, square cut cylinders.....where the liner broke off.

And that was no coincidence as cyl 2 already had a completely crack on one side, and was also close to failure. The third cylinder was ok, but I did not dare use it again.....so I had to start all over again with 3 new cylinders.

Jørgen