Low Speed Coil (H2) Winding for Dummies - by Tom Garcia

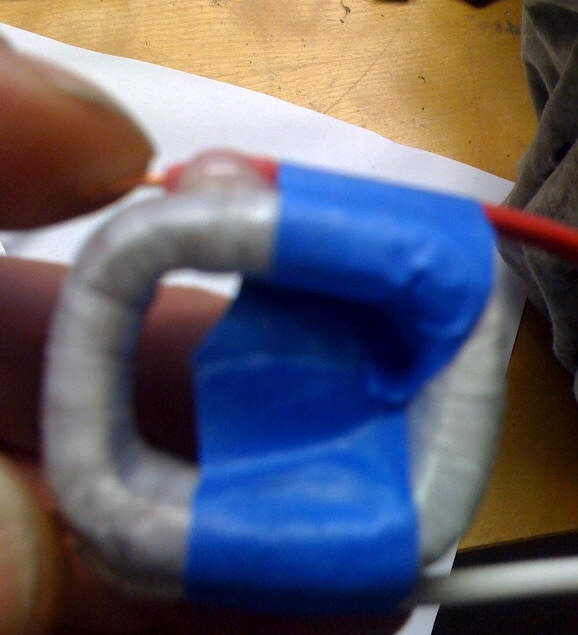

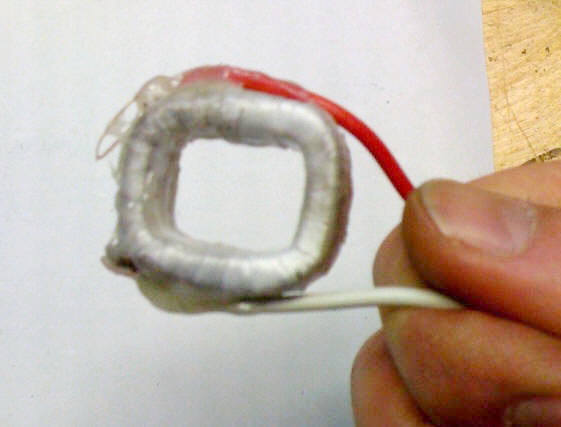

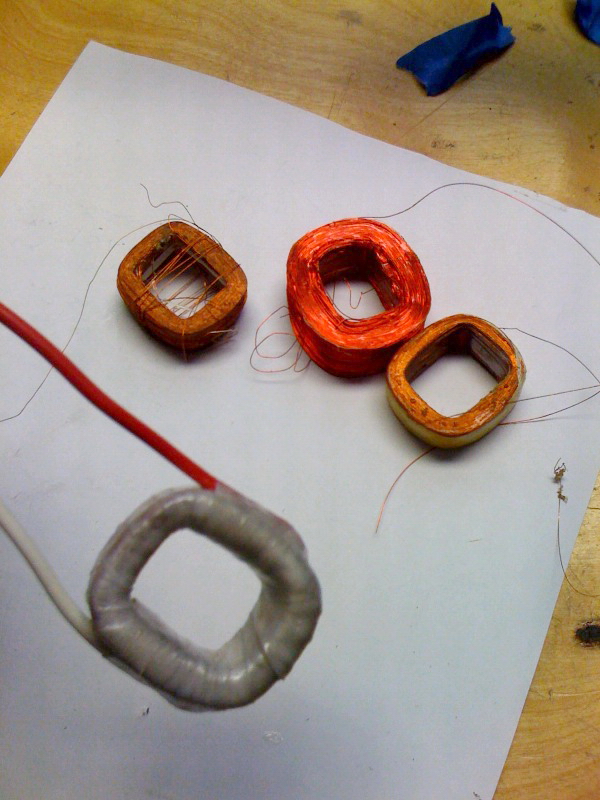

First you need a bobbin to wind this thing on... Two stick on door knob wall

protectors and a center core slightly larger than the dimensions of the

stator armature...

YES - the center core is made out of JB Weld... Whatcha expect!!!!!

The center core dimensions are .75" wide and 1.0" tall... 0.6" thick (the thickness actually determines the width of the finished coil).

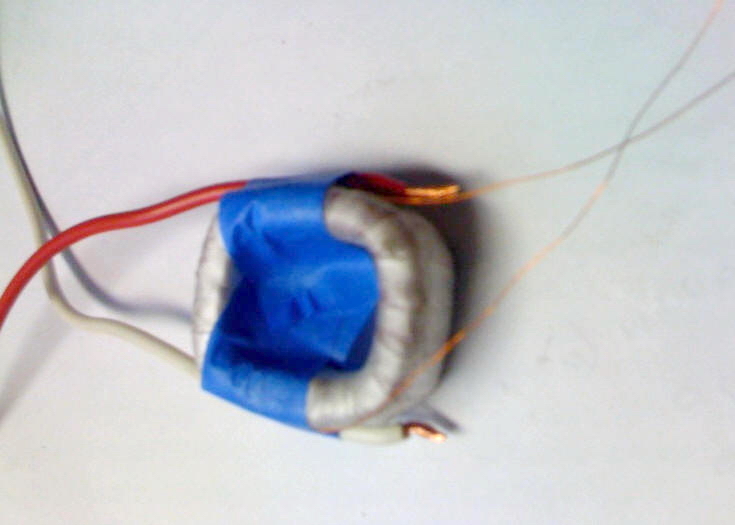

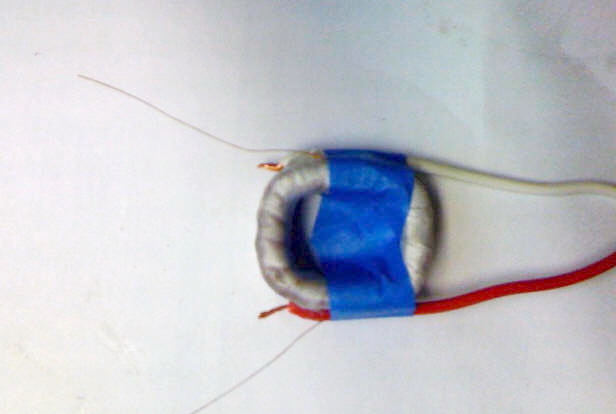

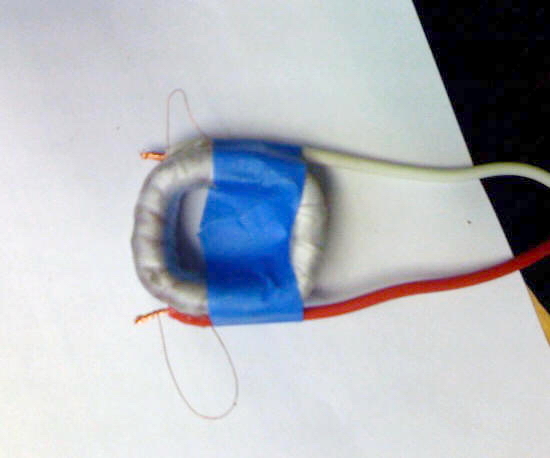

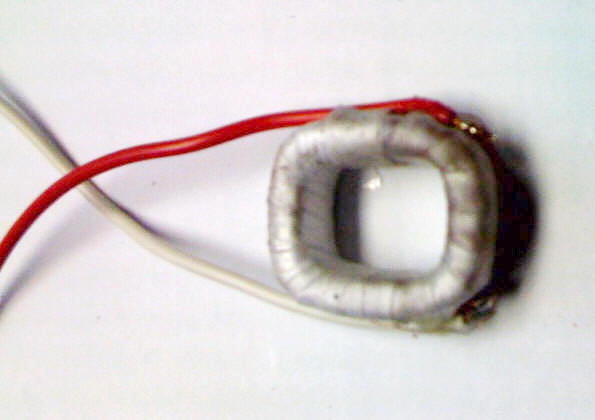

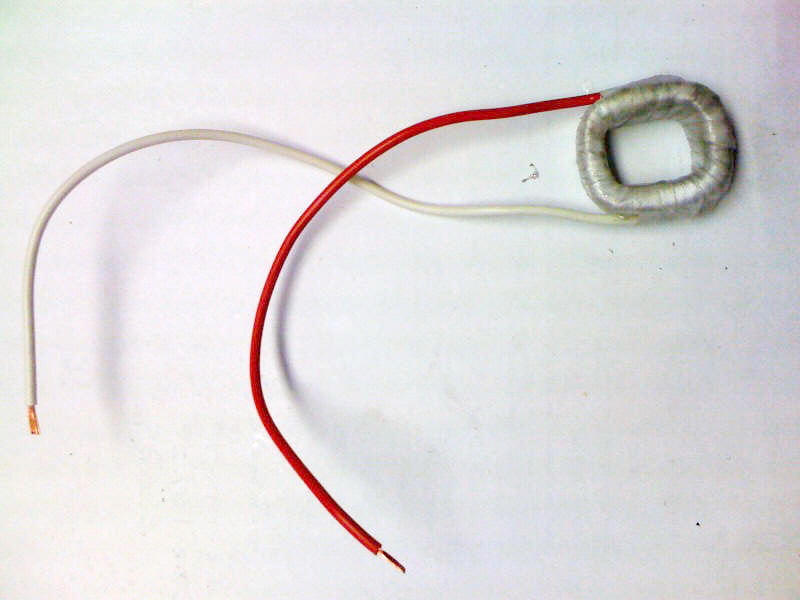

Here is what the bobbin looks like assembled and I've wrapped a base layer

of the ribbon (craft/sewing store) on the core... This adds a little more ID

play with the finished coil and also prevents the wire from getting in

between the center core and the side guards - this can make it impossible to

extract the core without destroying the newly wound coil...

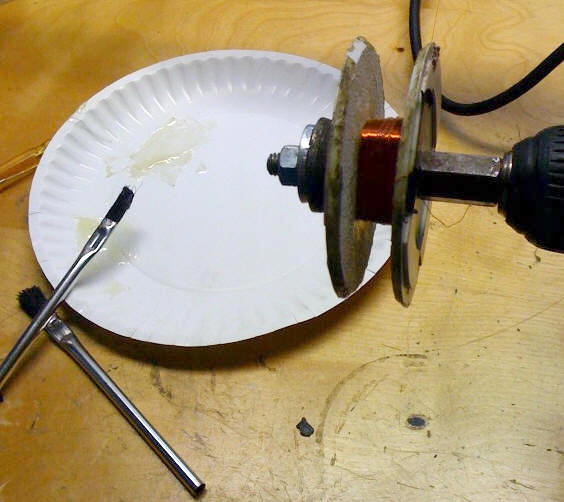

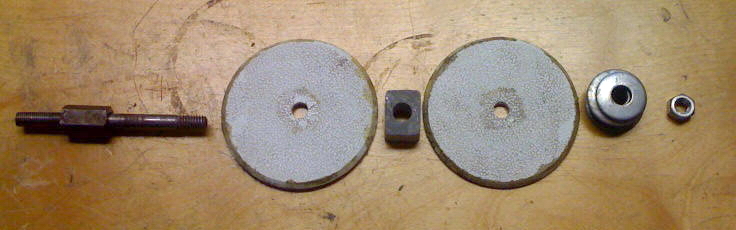

Here's the setup for winding - Variable speed drill stuck in the vise..

This is the wire I used - A 34ga enameled wire...

This winds up being just

slightly larger OD than the stock wire used for the low speed coil.

Here's the whole rig including the wire spool holder..

The way it is set up,

the drill is set to rotate so the bottom of the bobbin moves towards you and

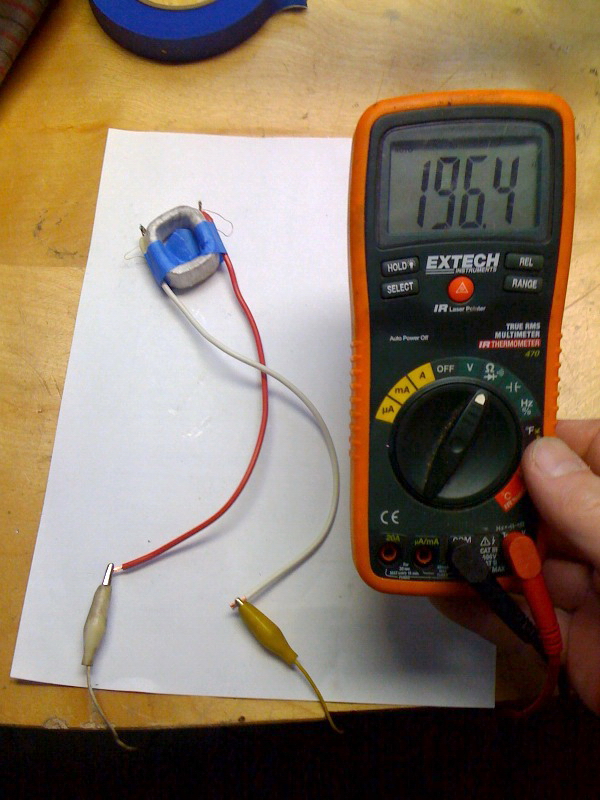

the top part moves away.. At least that is what works best for me. Wrap a

couple turns around the bobbin and then tape a short loose portion outside

the bobbin as shown here with the alligator clip for the VOM attached...