H2 Rotor Puller

Phil Ives

Hermosa Beach, CA

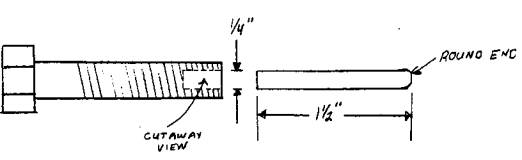

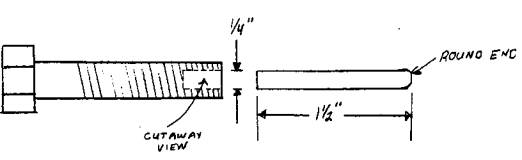

Tech tip: Since H2 magneto rotor

pullers are not available, and I could not find a 10 x 1.25 x 110mm screw to

fashion into a puller, I made one 1.25 x 35mm screw and a piece of 1/4" rod as

follows:

Drill 1/4" hole approximately 3/16" into end of machine screw (salvaged from

triple tree clamp or ?). Cut approximately 1-1/2" of 1/4" rod (or shank from

1/4" hardened bolt) and insert in tip of 10 x 1.215 machine screw. Now grease

the threads and remove the rotor! Be

sure to reinstall with anti-seize compound.

or

A shock bolt or fork clamp bolt may work...

The trick is to shock it off. A recipe for success usually

is:

Grease bolt

Make sure threads in rotor are clean

Insert bolt

Tighten it until you think it's about to strip

Hit the bolt (never the rotor)

with a 2 pound hammer. Don't wail into it and don't pretend. It needs a smart

tap.

Retighten bolt

Hit again

Repeat as necessary - it will come off between hit 1 and hit 4, 99 times out of

100

For

the '73 S2A you can use the swingarm bolt - it is beefy and full bore - with a

smear of grease on the end and a light touch of the air wrench, it pulls the

rotor right off.