H2 Porting Discussion

This is a condensed version of a thread from the KTOG message

board.

It has been edited to make it easier for the reader to follow the main topics.

Click

here for the full thread.

Topics

| Exhaust Port Width | Head Seal | Port Cleanup |

| Exhaust Port Shape | Lift Plates | |

| Carb Adapter/Carbs | Pistons | Sunken Heads |

| Chambers | Piston Cutting |

Exhaust Port Width:

LN: Anybody know how much (if any) you can widen the ex.port in

a h2 barrel with stock pistons? Thanks!

jeff kushner: Good rule of thumb is between 65-70% of the bore

but you might want to have a complete build plan before deciding on doing only

one aspect. There is a lot one can do to a stock H2 engine to get great power

without paying for "port work". Widening them seems to me to give you more torque but not much is the way of

sheer HP....but keep in mind that I do not own a dyno, just my impressions and

the H2 engine stock, has plenty of torque. The other thing is that I try to be

sure to leave 4mm for the ring pins, 2mm on either side. Nev has already told

you everything else you need to know about stock rings. The exh duration is what

opens up the power and by using the lift plates, you can "get away" with raising

it while maintaining good exh to trans ratios or blowdown timings.

LN: Ok, so the ringstops at ex.side is not a limiting factor?

That was my concern anyway.. Been reading (and posting) in Jorgen's awesome tuning

thread and my plan is to build me a lift kit instead of the current pretty wild

EBOS setup. Lots of midrange is my goal! But I'm used to snowmobile engines and

never bumped in to ring openings at ex.side before.. Shocked

jyrg: Increasing blowdown by widening the ex port seems to

me gives a good power increase in the upper power band.

It seems you are able to get better scavenging at almost all revs, and also 1

major factor:

You decrease combustion chamber pressure. That means the difference between that

pressure and the crankcase pressure when transfers opening is less. That means

the transfer flow increase as the reverse flow decrease.

I think that could be a reason for better power in powerband, and one do not

sacrifice power stroke (torque) by doing it.

Pistons:

jyrg: You may consider 70% as Maximum, With WOSSNERS. I would

be VERY careful with such a width..With stock pistons.

AND... If you're gonna try making a powerful H2, there are some critical elements... Piston brand is one of them.

To be honest: Wait until you have the wossners (or wiseco) before you start

working on your engine.

I just think stock pistons just cannot take for example my port map, but I have

never tried either.

Why? Because the wossners are considered best, and that's why I used them. So

should you, or you MAY (well, you will anyway, we all have) get into trouble.

Neville Lush: The ring pegs would allow about a 49mm wide port,

but I believe you would have trouble with the rings first. They are not as

flexible as the newer style wiseco/wossner rings. Many years ago I had nothing

but trouble with the same sort of mods and the rings would break and damage the

bores. I changed to newer piston/rings and the problem went away. If you get

good power from it the stock pistons seem to crack fairly easily as well. For a

mild engine, which still is snappy, maybe just widen the port a little and get

your durations where you want, keep revs down. Or buy a set of pistons :-)

LN: Very well explained, thanks nev! I will not go past 65%

before i rebore here and put in some wossners then. Have to find a way to fit my

carbs (tm40) to.. ebos would be the easiest way to go there i think? Have my

vm35,5 that i can use for now but the tm's should work best. Well first i will

order a liftplate and try to make me an porting template. Thanks to all for your

answers, very appreciated!

jeff kushner: If you are going to mod a stock engine, remove and replace the pistons as everyone has suggested....and I'm a true believer in Wossners. Once you hold one on your hand and compare it to anything else, stock or aftermarket, you'll see why. They are strong and very evenly weighted. You can build a mild engine with the stock pistons IMHO but as suggested, do NOT go very radical with the port timings or you may be replacing more than a set of pistons....and a set of cylinders are running around 600-700 these days, twice the cost of the Wossners.

Port Cleanup:

JohnnyO: One easy thing you can do is clean up your intake,

exhaust and transfers getting rid of all the casting flaws you'll be surprised

how much better they look when your done.

Piston Cut:

Battleax: I went backwards to normal logic, I cut 1.5mm off the

intake skirt of the Wossners, squished the heads with 145 psi and .863mm

clearance.

It softened the power below 2800 rpm slightly (much smoother from reduced power)

and pulls strong until 6000 and then there is no keeping front wheel down and

hasn't signed off at 9000 when I shift.

I'd do it again in a minute.

jeff kushner: Joe (Battleax) has built some very strong pulling engines and has also taken the time to do a bit of experimentation....his suggestions aren't guesses but the result of methodical mods.

Lift Plates/ Sunken Heads vs Cut Cylinders:

LN: Lift plates (1,6mm. copper gaskets) are on there way here.

Then my plan was to shave of what's needed from the barrels to get squish to

desired 0,8mm. But every lift kit I've read about here have sunk the head chamber

in to the bore instead, why is that? Obviously if one would have to rebore the jugs

with that design, you also need new head's correct? Not trying to start an argument

here, just trying to understand.

LeoM: When you sink the head into the bore, it's easy to go

back to stock timing by removing the lift plates and fit stock head again.

Trouble I found with the sunk head is that the circumference of the part this is

sunk in will be eaten away by detonation after awhile. At least, when you're

using a sharp tune. Me, I leave width of the ex port stock for best reliability

long term.

jeff kushner: The only reason I have used countersunk heads

with my last two "lifted" engines is ease of getting the work done. I cannot do

machine work so rather than ask someone to mill the cylinders, it's much easier

to find someone that will do the heads(thanks Joe B & Jeff D). The other

"advantage" is that in other cases, I asked the machinist to over-cut the heads,

in other words, cut them deeper than required which allows me, the builder, to

use the head gasket basically as a shim to get my required squish. Jeff D for

instance, cut my heads so that with the lift plates and gaskets accounted for,

using a .005'(.127mm) head gasket, my squish is EXACTLY at .717mm(Nev's work

convinced my to go a little tighter than the 0.8 I have in the H1) across the

board. If I find that is a little tight, I can swap out for a thicket gasket. I

had Cometic fab me multiple sets of varying thicknesses so I have lots of

choices. It costs a bit of cash but when I'm in final assembly, the last thing I

want is to be forced to wait a week or two for parts, besides, they always seem

to get used sometime down the road.

I don't know about other guys but I have never used copper as lift plates,

afraid that the greater expansion coefficient of the copper compared to the

steel liner(I think copper is around 25-30% greater) would cause problems.

Please let us know how it works out. Also when using lift plates, I typically

aim for the 2.2-2.6mm range including gaskets but it depends on the bike.

Neville Lush: I am learning things here. I have always

preferred copper lift gaskets as I seem to have less trouble sealing them than

alloy. It may be a placebo effect however. The first reason for using them, in my

case, was to stop base gaskets getting sucked in. That's a story longer than I

have right now. I never once thought of the expansion factor. :-).

jyrg: I also use copper gasket.

LN: Thanks guys! I have to settle for a sneaky mild tune this year so I wont go radical with the porting for now. But I prob. will have the cyl. milled, my local machine-shop already made me a holding fixture when they trued one of the ebos cyl. for me. I had the same trouble as Nev with leaking base gaskets (ported crankcase) before I moved on to copper.

BBP: LN.............Leo is

correct.........I thought it kind of weird, but I did think about options for my

cylinders..........but I could remove the lift plates and go back to using a

paper gasket (and use last years squish heads as the deck would be ok), or a

.5mm or 1mm or 1.5 lift plate.........with new heads.

At this point, I don't really see me ever doing that............and my TMX38's

probably would not fit anyways (but I could).

The only reason I have sunken heads as they were available and nicely

done.........with my 2mm lift plates (no paper gaskets, use three bond on the

lift plates)............I have a tall deck height of .090"..........the sunken

heads drop down .050"...........so I got a good .040" (1mm) squish.

So I could have just had the cylinders decked to .020" above the piston, add a

.020" gasket for a .040" squish, same thing (but could never use those cylinders

unless lifted).

SSO or Ralph's sand cast probably better heads.

I had my Inlet Ports machined UP at about a 5 degree angle, that made my very

tall TMX38's clear the crankcase (barely).........it's in the Hot Rod

Thread........page 50 on up.

49mm wide is a good setup for the street motor, little arc across the top, upper

corners a slight bit more squared up (not square though).........left the bottom

corners with more radius than the top..........this is to keep the transfers

from Not short circuiting and blowing out the EX port..........and you can see

it working on the piston crown........IMHO and some others here.........had to

lower the EX port to match a bit below the piston crown (very

little)...........after you do a mock up and check it first with lift plates

installed as a test

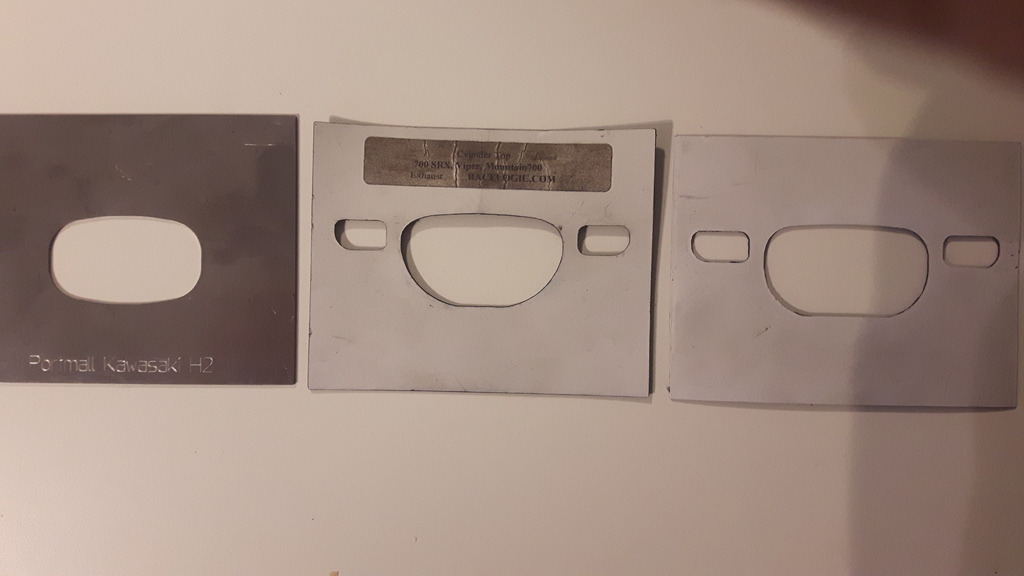

LN: Finally some progress! Wisecos 71,5 are on their way

here! But I need some opinions on what porting template to use? First from left

is a stock radius ex.port with a 70% width of my bore and a 1mm. Rise (I'm using

1,6mm. Liftplates)

The middle one is a "sportport" template from racelogic (+1mm. Rise of main ex)

for my Yamaha srx 700 sled (69mm. Bore) witch made 163 crank hp on my sled with

several other mods (139hp stock on same dyno) Last one is my own design

(2mm.wider sub.ex and widened main ex.bottom) very little testing on the last

port job (no snow) but "butt dyno says: improved/widened powerband and it's a

blast to ride!!

Sled templates has a 73% ex.width (on top) witch seem to

work fine so I'm considering trying that design (but with stock h2 radius

port roof) to get some extra area on top? Talking about copy only the main

ex.port here, aux.ports would be neat to have those.

Your opinions please!!

jyrg: Sorry Lars..........it's hard to get room for aux ports on a H2 due to the cylinder studs. But yes.....the aux port design is superior to what we are stuck with.

BBP: I went 49mm wide, 1 mm raise, 2mm lift plates (which is 1.5mm lift)...........port is a bit more squared up at the top of port corners, left some radius at the bottom corners as to not "short circuit" with the transfers...........got rid of the hump exiting the bottom of the EX port.......removed a lot of aluminum to get the port shape nice. That lift uncovers the bottom of the transfers also, as stock, they are below the piston at BDC.

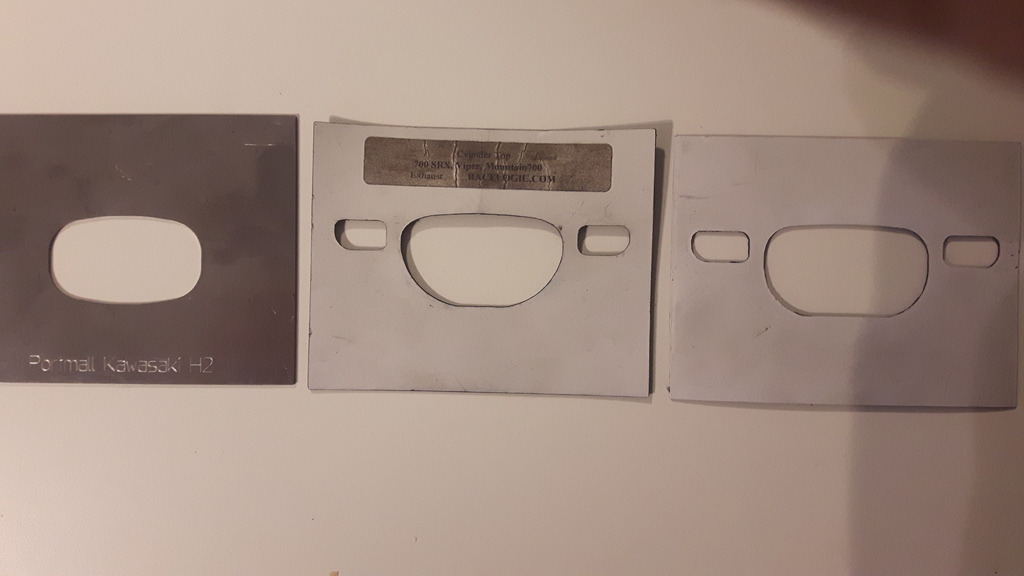

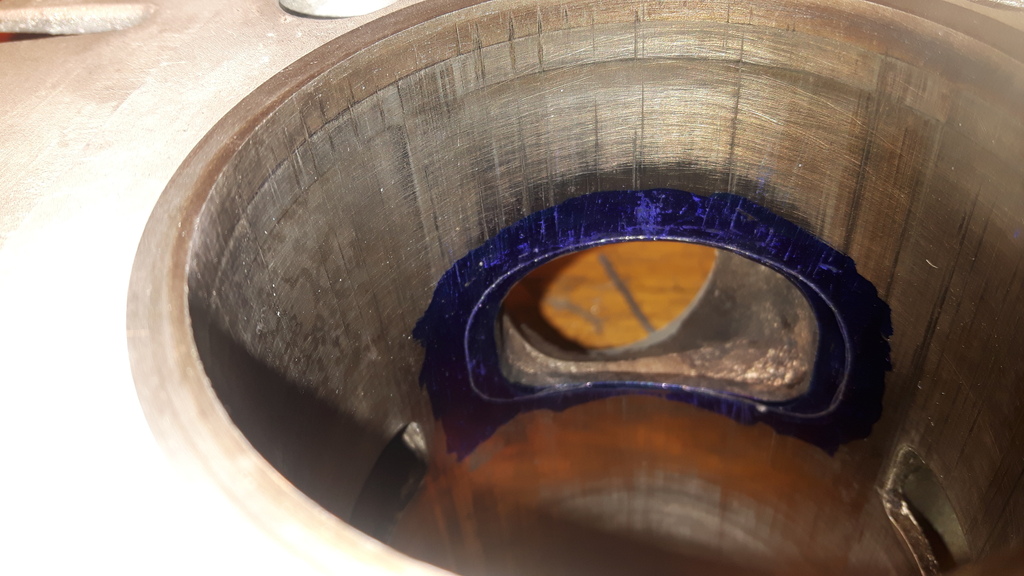

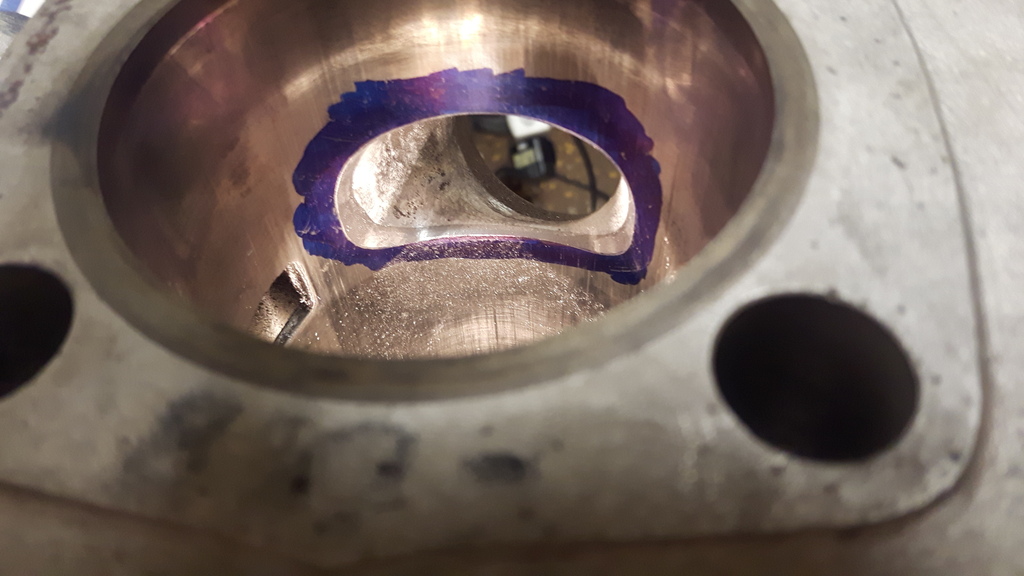

LN: Correct phil, I'm doing a lift job

on a set of stock early jugs now. And I've just finished my porting-template for

this and decided to just go stock port shape for now. Don't know how others do it

(please show us) but this is how I like to do it so all 3 cyl. (hopefully..)

will have the same shape and height.

Traced stock port and then gave it to a buddy at work and simply told him I

wanted to widen it and raise 1mm. to be 70% cordial with a 71,5mm bore. He then

did his cad-magic and then lasercut the steel template.

Then I place the template over some magnetic rubber material and cut it out.

Then I put some dye-ink in cyl. and carfully place the template and trace it,

almost done, just a little carving left..

12dot: Some of us that have been "around

these bikes" for a while, still do it the "old fashioned" way.

Piece of paper and a soft lead pencil to get rubbing of existing port shape(s)

map - make the adjustments (changes) on the piece of paper - cut them out to the

new shape - re-insert the piece of paper - mark new shape - very similar to

yours (just not quite as good as your method).....

Lars: Sounds like a very good way to go

about it to me.

I'm glad you decided to stay at 70% cordial. I have no personal experience with

this (yet) but I would think going to 73% would be asking for trouble or at

least going through rings pretty fast for not a whole lot of gain.

On my 500, I traced the stock port shape as high as I wanted it and made another

trace an additional mm higher up as I wanted to square up to the ex.port roof a

little. The extra line made it easy to see what I was doing and make the port

symmetrical. In my mind a narrower more square port seems better than an

extremely wide port as I believe the widest possible port must be more rounded

and blow down area suffers.

I don't know if you're going to do a lift, but I also lowered the ex.floor to

compensate for the lift and then some. With the port floor at or just below the

piston crown at BDC, you get a big "triangle" of cylinder on each side of the

port bottom at BDC. Even though most of the ex. flow is done at blow down, it's

still pretty hot in there and those slivers sticking out will get very hot and

do nothing good. Lowering the floor and squaring it off some ( I guess it could

be made pretty square as piston speed is very low near BDC. ) will hide that

part of the cylinder from the heat and keep the cylinder cooler and be able to

transport more heat away from the piston/rings.

LN: Very interesting Lars, and thanks for the compliments!

I would be careful about making port roof to flat or you may end up with a light switch motor like I have now with the cyl. pictured above.. Shocked but hey, they have 198° duration so.. Yes I'm lifting a little with 1,6 copper gaskets, want plenty of midrange grunt.

jyrg: After the BD phase, you do not

need much exhaust port area, compared to the ex port area further up in the ex

port. The extremely squared port shown above, most likely short circuit a lot.

And short circuiting prior to powerband robs power, as the fuel never ends where

it is supposed to end.....in the combustion chamber.

Most of the short circuiting in powerband though, is stuffed back in due to the

returning wave entering after piston closing transfers, and is useful.

I use more of a "D-shaped" profile, as shown in the tuning thread.

But heeey.......a ex port like shown from LN, makes the powerband

hit.......quite funny.

But, for a street application: Not so good, as we need better low/midrange to

accelerate in high gear at lower revs.

LN: Amen to that! But remember, that

extremely square design is Ebos not mine. Think they where done in the early

90's.. They have a 72,5 bore and still look pretty good, but piston clearance is

a bit large, around 0,15mm. if I remember correctly? Maybe I could nicasil them?

Have thinking about trying to gain back some midrange in them with a (big) reed

conversion but don't know if it's worth the effort? If i do that is it best not

to add extra boost ports over intake port? Air filter fitting is also gonna be a

issue of course..

Lars: I'm on board with the short

circuiting thing. The squared off floor might not be the best thing to do with a

very wide port. But the point isn't to get the most area down low, it could be

implemented on a port that is narrower down low and wider up on top. Like the

sled port shown earlier. The point is to make the engine run cooler.

Below is a quote from Nev that he posted on my top end rebuild thread.

Neville Lush wrote:

For the H1. I would make the lower port window up to 1mm below the piston at

bottom dead centre. This is important in my view because it removes the step for

the hot ex gas to bump into on the way out. If there is a step, that piece of

sleeve will be hot and get hotter. The engine will be more prone to sticking the

piston, so I get rid of it and a little more. If this is done well I can run

another 5 psi CCP.

That last sentence stands out to me. Being able to run higher compression surely

must benefit low and midrange.

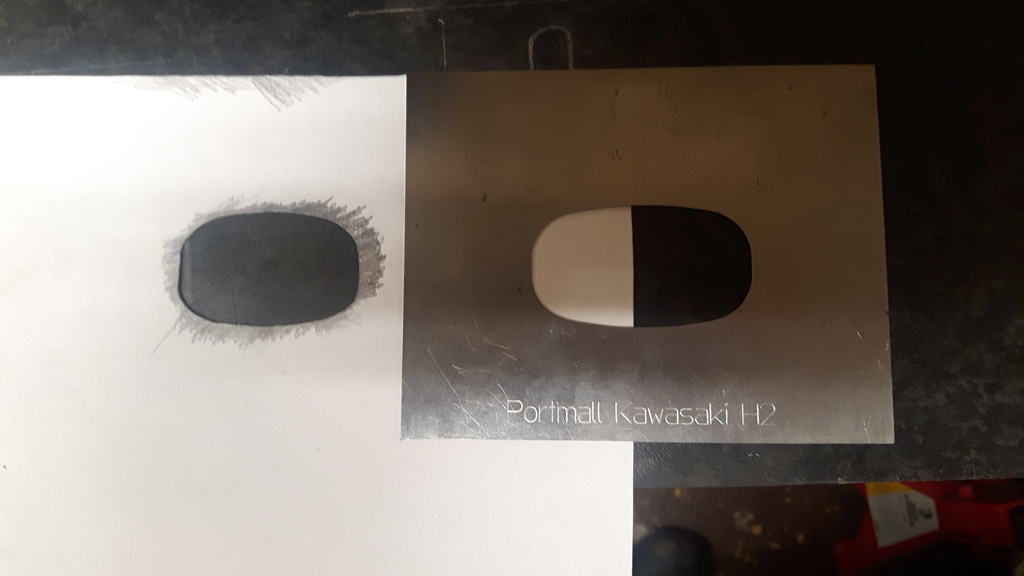

LN: Pre-ported my jugs at work the other

night with an air grinder, very effective!! I left about 1mm. all around

(didn't dare to go closer. )

Finished this one at home today and I think it's ready for sanding/polish, I

will address port floor later when I do a mock-up.

BBP: LN...... Yep, looks real good, as long as you get the port shape in the cylinder done. Cleaning up the outer port and polishing can be done afterwards. I removed quite a bit of aluminum on the out side of the ports............sanded, then polished. No funny high or low spots, just a good smooth flowing port. Then mothers polish on a cotton small dremel buffer.........the rest by hand.

LN: Haven't checked durations yet (Embarrassed). Will do at mockup but with 1,6mm.coppergaskets plus 1mm. additional ex.lift. I should be well under 190° ex.dur. I guess? I really like to work on these cyl. even though it's a lot of material to remove in them.. But at least they don't have those (very) small aux.ex. ports one have to struggle with in sled triple engines, they are a real pita to get done! Especially the little port-tunnel. But they really wake up the engine so you can't leave them undone.

BBP: LN..........You should probably end

up around 187 EX (stock 178), 126 Transfer (stock 118)........Intake 145 (stock

150......more duration than lifted).

Mine is lifted the same as yours (no paper gaskets on mine though, three bonded

directly to case, cylinder base)..........my EX was raised 1 mm as

well...........made a simple dial indicator from the zeel site and used a small

earth magnet........easy.

I think I am going to pull my cylinders and cut the back of the piston skirt to

get some more Inlet timing back..........thinking 3mm...........(1.5 to

compensate for lift, so add 1.5mm of increase) so would get me in the 154 IN

degrees area.

The Bike runs real good now, good low end and strong all over, I wanted to test

it first with less IN duration with the 38's...........and it works well (I

could leave it alone actually, but that's hard to do)........something tells me

it will be better with some more IN duration.

This is kind of "Middle of the Road" port timing, and makes for a for a very fun

street bike..........I love the 38's, they really suit it

well...........responds well to jetting and zeel changes too.

LN: Ok, I got you wrong then, thought you lifted yours 1,5 (2mm.plate) Phil? Cool if we have same spec though. About in.duration, I run 4mm. cut (around165°?) now on my ebos cyl. and low end is actually pretty decent! It's midrange i don't have! But I have tried it with uncut pistons to, with very little change in midrange! Low end was stronger of course.. so I definitely will compensate in.dur. on my lift job. Maybe i try 2mm. first, i don't really need more low end than i have now..

BBP: LN..........we should have similar

port timing..........and similar motors. The nice thing about the 2mm lift kit

is uncovering 2mm more transfer port..........that's a nice boost in itself. My

piston now is flush with the bottom of the transfer at BDC...........rather than

2mm below the piston crown as stock. Maybe they did that to cool the piston for

some reason.

Agree on the piston skirt mod, I am going to follow Jorgen's Curve to match the

port shape...........thinking 3mm or so..........we will see. I'll have to tear

all apart again (that's OK).

I think you are going to run TM38 box slide carb's right ?..........I would

think they should work well.

jyrg: LN: I think your lack of midrange

comes from 2 sides:

1: Your extremely square ex port makes one hell of a exhaust pulse. That is

good.......in powerband. But is not good in the 4000-powerband (mid range) area

due to the hard returning wave messes up scavenging.

2: Your pipes may have an aggressive baffle cone? In that case, your total

is.......low midrange, effective powerband.

And yes.....running with good pipes that have the good suction ability actually

make your powerband AND midrange a bit stronger with more inlet duration.

That is because at a certain point (I tried to describe that in the tuning

article that mraxl posted on his resource site) the suction "is greater than the

piston pumping capacity)......and I think that "crossing line is on the 4500 rpm

area on a H2. We must never forget that our beloved triples engines are NOT a

pumping device like a foulstroker, when in powerband, but a true resonator

(providing you have good pipes).

And as said........I think the crossing line where you "start getting" into the

resonator ballroom starts in the 4500 area.....this is not digital, but more of

an analog "thing".

(I don't have the correct English words for it, but I think you will

understand).

I run very conservative inlet duration numbers, just because I like that low low

end grunt you have on a stock H2, on my ported H2's as well. I often launch in

second gear, because I kind of do not need first gear, and I like cruising out

of roundabouts in high gear 1500 rpm, and accelerate without downshifting.

LN: You're getting old Jorgen, buy a Harley.. LMFAO kidding aside, I'm 100% with you about my lack of midrange! But baffle cone is pretty mild at around 8° thoe.. And I have tryed alot of pipetuning-lengths and even tryed stock pipes, still no midrange! So that square port must be the main culprit? Pipes work great with stock cyl. Anyway, I guess I will find out how they work with the mildport/lifted setup soon enough.

jyrg: Yes, But don't let the hard

powerband feeling fool you. With stock cylinders, your powerband "hit" is WAY

weaker than with them old ebos cylinders.

So......if your midrange power is same, it will feels weaker due to what comes

next: A brutal powerband.

If the powerband is lazy, as with stock cylinders, the "step" from midrange to

powerband is much less, that means your butt dyno will feel the midrange as

stronger than if you have same midrange power but a hopped up brutal powerband.

It's really only one solution: DYNO

If you live close to Oslo, you're welcome to my workshop/dyno shop.

LN: That makes sense Jorgen! I would love a roadtrip to Oslo! But.. I'm as always on a budget but I'm definitely gonna consider it! Anyway we (family) are going close to Malmo (800km. from here) for vacation this summer. I would love to have my bike with me and dyno it at Ebos which is located in Malmo but don't know if I can make it? If I don't make it I have just 400km. to Oslo..

skipper: Nice pipes! are those tomcats

or ebos?

LN: No, they are in fact sled pipes (yamaha srx 700) which are

joined with fbg headers on my garage-floor with a mig welder.. Looks like shit

really, but work pretty good . But they look a little better in the pic. On fb

you saw, as I was trying a single cone diffusor back then. Now they are back to

that orginally multicone diffusor witch seems to work a little better.. I will

put up a pic. or if I make to your rally you can see them in person.

BBP: LN..........we should have similar

port timing and similar motors. The nice thing about the 2mm lift kit is

uncovering 2mm more transfer port..........that's a nice boost in itself. My

piston now is flush with the bottom of the transfer at BDC rather than 2mm below

the piston crown as stock. Maybe they did that to cool the piston for some

reason.

Agree on the piston skirt mod, I am going to follow Jorgen's Curve to match the

port shape. Thinking 3mm or so..........we will see. Will have to tear all apart

again (that's OK).

I think you are going to run TM38 box slide carb's right? I would think they

should work well.

Jorgen........that's a great explanation and makes total sense (your English is

actually very good).

LN: So what do you guys use for sealing the heads when running no headgasket??

BBP: I get the decks flat on a

piece of glass with 400\600\800 sandpaper...Same with the head's if not sunken.

Tape up the heads and spray two coats of Copper Coat spray, let it get tacky.

Torque in a cross pattern to 24 ft lbls (not 30.7 distorts ports). After cool

down, repeat 3 or 4 times.

For lift plates, always use anti seize on the studs FYI. On the 2mm lift plate,

I used Three Bond as NEV suggested, no paper gaskets, no leaks at all. I pulled

the cylinders off today.....easy, just rock them once or twice. The lift plates

stayed glued to the crankcase, so I am just going to re-glue the upper half lift

plate tomorrow when I put it back together.

LN: Ok so copper spray will work then, great thanks Phil!

jyrg: Same as any high temp 300C silicone sealant, like Permatex Blue, Reinzoll

or even Biltema Red

LeoM: Been using bathroom silicone for years. But once I started to degrease the

surfaces, it became hard to remove the heads after use. Now I roughen up the

mating surfaces with a file which also serves to check flattness. Apply any

silicone sealant, a very thin layer spread out with finger, let it find some

moisture from the air during 2-3 minutes, and then assemble.

Removing heads is then possible by putting a thick screwdriver between head and

cylinder and lift.

Have found copper headgaskets tend to blow once you get serious HP. And don't

forget to add the "O-ring" groove (which it isn't) in the head to increase

surface pressure at the same bolt-torque.

LN: Thanks guys! Leo, I don't have any "o-ring" groove left in my heads, will it

seal anyway??

BBP: LN....I don't have any O ring either. Mine are sunken though and that

probably helps. Jorgen and others do it all the time with no head gasket. Give

it a go I would say. I only torque to 24 ft lbs, I got that from the Drag

Racers, Bill B and GW1626.They found ports distorting when honing at 30.7 ft

lbs. I could see lines by each stud in the barrels. Not anymore.........and

maybe less chance of cracking a head IMHO. You will know if they leak. Mine

leaked until I got them flat on a piece of glass (cylinders and heads).

LeoM: Good chance they seal without the groove. More certain with groove, even

with less torque than most use.

LN: Ok sounds good, unfortunately I had a major setback today, the machineshop

couldn't deck my cylinders due to broken equipment. I don't have time to find

someone else to deck them (aiming for Norwegian rally next week) so I will put

it together without liftplates. Should run decent that way, I hope!

LeoM: You'll be OK, just check squish clearance and keep ears open while

travelling. A high pitch sound coming from the cylinders indicates lean and

detonation and thus troubles ahead. When running close to deto, you'll get best

fuel mileage though! Sharp H2's get 5 to 6 litres/100 km! Enjoy the

rally-weekend!

Carb Adapter/Carbs:

LN: Yep, squish is about 1mm. So I should be fine. Wow 5-6 liters/100km is

amazing!! Here's a pic of my redneck style carb angle adapter. Best I could do

in the tight time frame.. air filter fitting is tiiight!

BBP: LN........I like it for a quick fix. If somebody

would make some manifolds with a 5 degree up angle there would be no reason to

have to machine the Intake surface to fit TMX38's. It will be cool to try it

without lift plates IMHO. Then you can feel the difference between the

two..........you will be fine.

So, you are running the rack type HSR, I believe, carbs?

jyrg: In Sweden they are called "raggare". In Norway we are all Vikings. Vikings

eat "raggare" for dinner! Or what, Lars?

Lars: We sure do! Razz

Too bad about the machine shop, but kind of nice to get to know what the lift

alone does to the engine too.

LN: Those are Mikuni TM 38 rackstyle sledcarbs (ski-doo mach z) offset bored to

40,2mm. Vikings are like sissy girls compared to a real raggare!! Heres a real

raggare story from back in the days (70's): My brother and his "gang" of raggare

was dismissed from Norway by the cops after they had been sliding around on the

grass in and old Mercury in the middle of a sockergame!!!

pg10