Troubleshooting "No Spark" on Points Ignition

It is important to have a fully charged battery. It is also important to have the engine grounded to the frame. On engines that are rubber mounted there is should be a ground strap running from the sprocket cover to the rear engine mounting bracket.

Sparkplug gap needs to be per spec. Resistor plug caps/wires are especially detrimental to points ignition performance.

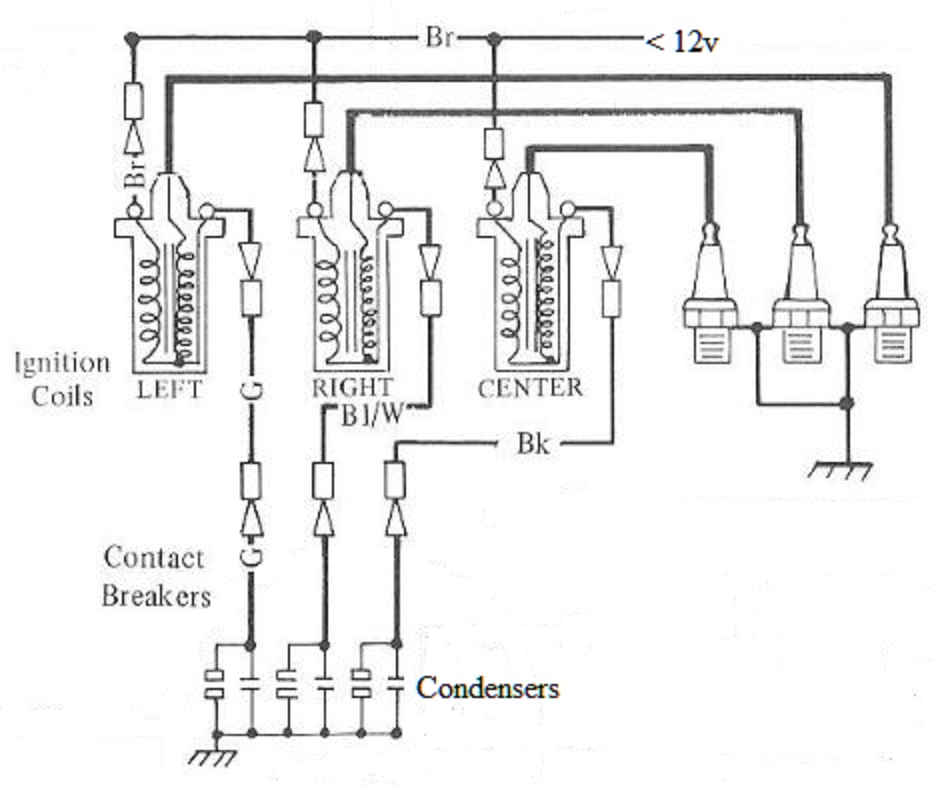

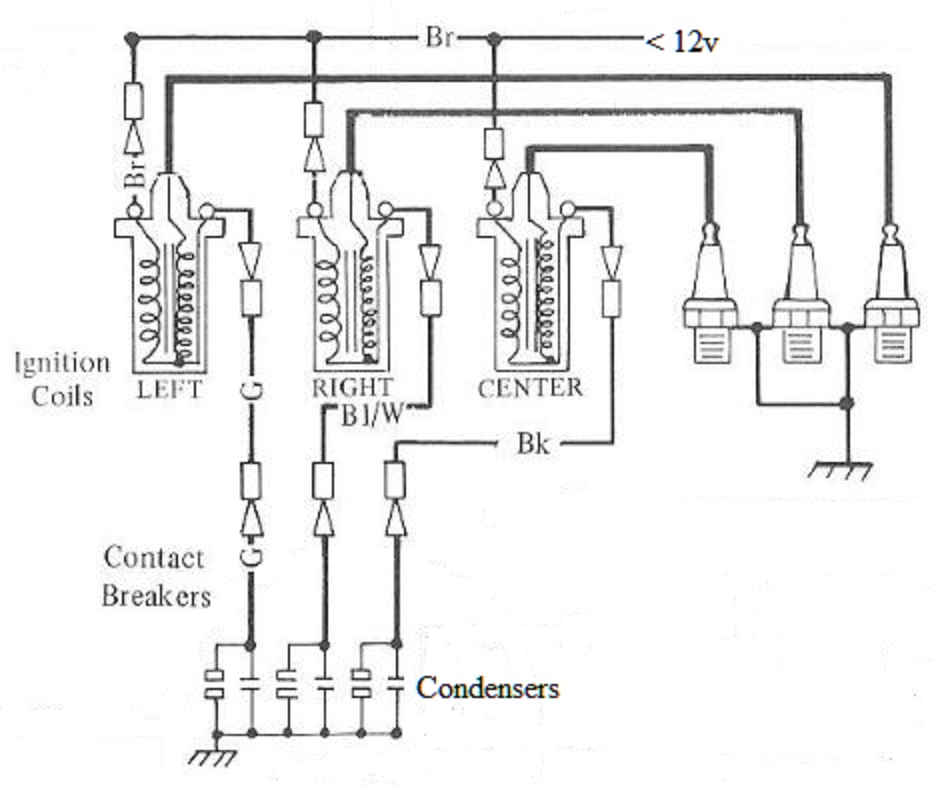

Remove the ignition cover and check for battery voltage, with key "ON", on each set of points (preferably with analog meter). There will be no voltage if the crank is positioned so that a set of points is closed.

With the meter attached to a points set, manually rotate the crank 360deg. As the crank rotates the voltage should drop from battery voltage (approx 12vdc) to 0 volts when points close. As the points open there will be a small spark. Repeat the process for each points set.

If battery voltage is not measured at the points set:

- Kill switch is on (if model configured).

- Points are not adjusted properly to open.

- The wire connecting to the points set may not be properly connected between insulators on points. Remove wire and check for battery voltage on it.

- Condenser may be shorted. Remove condenser lead and see if voltage is then present.

- Wiring between ignition switch/coil or coil/points is not intact or poor connection at connector.

- Defective ignition coil.

If battery voltage does not drop to 0vdc:

- Points are not properly adjusted to close.

- Points contacts are contaminated. Sometimes new points have a preservative applied to prevent corrosion. Clean contacts with rubbing alcohol or contact cleaner.

- Engine is not properly grounded.

Note: This procedure will allow one to resolve "no spark" issues but does not insure that the proper coil/plug is being fired. Crossed wires can be a problem. Resistor plugs or caps, especially on points ignitions, can cause problems.

To check condensers:

- Ignition off

- Select a mid range ohms scale on an analog

multimeter

- Remove condenser lead at points

- Connect meter between ground and the removed

condenser lead

- The meter should deflect and ease back

- Reverse meter leads and repeat... expect same

meter deflection results

If meter does not deflect, the condenser is open.

If the meter shows a steady resistance, it is shorted. If in doubt, all should

read the same.

To check points ignition coils:

-

Primary, between coil terminals, should

measure about 4 ohms.

- Secondary, between any terminal and plug lead, should be about 6.7K ohms.

Note: 12v coil supply wire is red on some models