SOLID STATE VOLTAGE REGULATOR

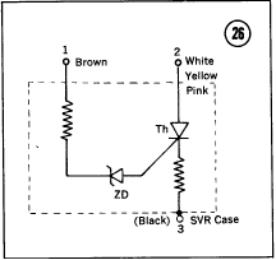

Models KH400, KH250, and S series are equipped

with a solid state voltage regulator (SVR). This unit consists of a zener diode

(ZD), a thyristor (Th), and two resistors, as shown in Figure 26.

Models KH400, KH250, and S series are equipped

with a solid state voltage regulator (SVR). This unit consists of a zener diode

(ZD), a thyristor (Th), and two resistors, as shown in Figure 26.

KH250 and S Series

Troubleshooting

If a malfunction of the solid state voltage regulator is suspected, it

may be checked by the following tests. However, bear in mind that if the

battery is low, the regulator will not work properly even though it may be in

good condition. Therefore, be sure that the battery is in good condition and

at or near full charge before attempting to trouble shooting a suspected

malfunction.

1. Measure

resistance between the brown wire and the case. Resistance must be greater than

1,000 ohms.

1. Measure

resistance between the brown wire and the case. Resistance must be greater than

1,000 ohms.

2. Measure resistance in both

directions between terminals 2 and 3. Resistance should be essentially

infinite in both directions.

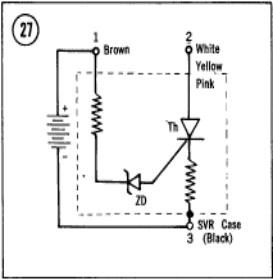

3. Connect the motorcycle

battery to the regulator as shown in Figure 27. Be careful to observe

proper polarity. No current should flow in the circuit between terminals 1 and

3. Measure resistance between terminals 2 and 3. Resistance should be essentially

infinite.

4. Connect an additional 4 to 6

volt battery in series with the first battery to make a total of over 16 volts

across terminals 1 and 3. If current does not flow, either the zener diode or

the first thyristor is defective.

5. Replace the regulator if it fails any of the

foregoing checks. If its condition is still doubtful, check it by trial

replacement with a known good unit.

KH400 Troubleshooting

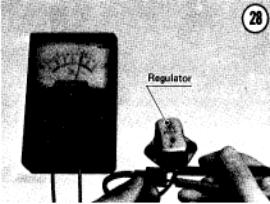

1. Check the

resistance between the black and yellow/green leads (Figure 28). Resistance should be between 1,000-1,200 ohms.

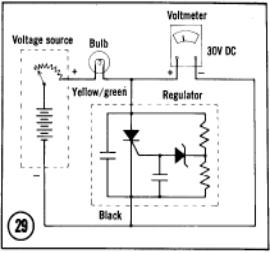

2. Connect

the circuit shown in Figure 29 using

a suitable power supply. Set the voltmeter to the 30V DC range. Turn on the

power supply; the light should be off. Gradually

increase the voltage from 8 to 14 volts; if the regulator is good, the bulb

will light between 10-12 volts.

3. Replace

the voltage regulator if it fails either of these tests. If its condition is

still doubtful, check it by trial replacement with a known good one.

Handling

Precautions

Handling

Precautions

Certain precautions must be observed when you

handle or service the solid state regulator. Failure to observe these may

result in damage to the unit.

1. Be sure that the mounting screws are tight.

2. Always be sure that the main switch is off before

connecting or disconnecting the unit.

3. Be sure that the unit is mounted securely.

4. Be sure that the wires are connected properly.

Improper wiring will result in damage to the battery and regulator.

5. The battery must be charged to near full capacity

for the regulator to work properly. If the battery is very low, charge it

before installation.

ELECTROMAGNETIC VOLTAGE REGULATOR—H1

Operation

Some alternators use separately excited field

windings. Such alternators require a more complex regulator. As engine speed

increases, alternator output tends to increase. It is possible, however, to

control alternator output by controlling its field current, which is used for

excitation.

Some alternators use separately excited field

windings. Such alternators require a more complex regulator. As engine speed

increases, alternator output tends to increase. It is possible, however, to

control alternator output by controlling its field current, which is used for

excitation.

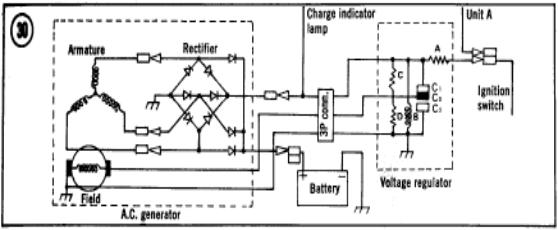

Figure

30 illustrates the situation

at low engine speeds. The rectified alternator output is applied to coil B.

However, since the output is low, the magnetic field developed by coil B is too

low to open contacts C and C0. Under these conditions, field current

is supplied by the battery through the ignition switch, and is at its maximum

value.

As alternator output voltage tends to increase,

coil B develops more magnetic force, which breaks contacts C and C0.

Field current is then supplied from the alternator output through resistor C.

Resistor C limits the field current, and thereby reduces alternator output so

that contacts C, and C0 again close, repeating the cycle.

At high engine speeds and light electrical

loads, the action of the upper and center contacts is insufficient to control

alternator output. As output voltage continues to rise, coil B pulls the

movable contact C0 down to the lower contact C2. Under this condition

the field is grounded, and alternator output drops to zero. As it drops, the

movable and lower contacts separate, and the cycle repeats.

Regulator Testing

The most common causes of voltage regulator

trouble are open wires or short circuits. To check the regulator, proceed as

follows.

1. Remove the regulator.

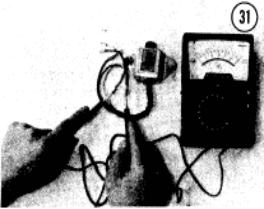

2. Measure resistance between the brown and black

leads (Figure 31). Resistance should be approximately 55 ohms.

3. Connect a

voltmeter across the battery terminals. Reconnect the regulator.

4. Start the

engine and run it at 5,000 rpm. If the measured voltage is 14.5 plus or minus 0.5, the regulator is OK.