Triple Oiling System Overview

Triple oiling systems are divided into two groups. The Superlube system feeds directly to bearings and piston/cylinders. It is used on H series. The Injectolube system does not directly feed oil to bearings. It is used on S series models.

Tanks

Some early model Triples (pre '72 models) were fitted with ventless oil

tanks. Vented tanks will have a clear vent tube attached that goes over the

frame rail. It is important to note that this tube must not be collapsed or

kinked to deter venting.

Ventless tanks were fitted with vented oil caps. Although some '72 - '73 model

oil caps will fit and are similar to pre '72 models, these caps are not vented

and must not be used on non-vented tanks. It will prevent oil flow.

All models are fitted with an oil filter at the tank outlet. Early models had a

filter attached to the banjo bolt at the outlet. Later models have a screen

inside the nipple cap.

Late models had a screen in the outlet nipple.

The filters should be inspected and cleaned on an annual basis.

They can become clogged and prevent oil flow. Some oil mixes of dino vs.

synthetic oil can cause coagulation of oil and block these filters.

The late model filter nipples are prone to crack and/or break when undue stress

is applied on the attached line.

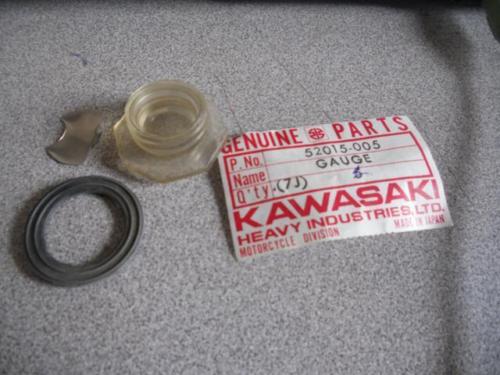

The sight glass in late model tanks are prone to discoloration and cloudiness.

They are NLA from Kawasaki.

New sight glasses are available thru Suzuki and are identical to the Kawasaki part. Suzuki part# 44600-31831. If the sight glass is over tightened it will strip the threads in the tank. Leaking sight glasses can be solved by using a small amount of case sealer to the tank mating surface.

Tank Oil Line

The tank oil line is 5mm ID (same as fuel line). A 3/16" line will suffice. Use of 1/4" will require clamps. Replacing the original line with clear will allow viewing of oil flow.

Pump

There are two types of pumps used on

Triples.... a three hole pump and a four hole pump. The four hole pump is used

exclusively on the H2B/C. All three hole pumps are interchangeable although pump

output varies with models.

http://kawatriple.com/modelspecs.html

Both pumps are positive displacement and output is controlled by both engine

speed and throttle position.

The pump model is stamped on the lever, S1-1, H1-2. etc. Early H1 had no

marking. See service bulletins for various modifications that may have been

done.

http://kawatriple.com/bulletins.htm

A breakdown of the two types may be seen here:

http://kawatriple.com/partid/oilpump/oilpump.htm

Oil line fittings are attached with an aluminum crush washer below the fitting

and a lock plate on top of the fittings. These crush washers are designed for a

one time use. Repeated use will cause air leaks to be introduced into the oil

lines and oil leaks. Stat-o-seal or dowdy washers placed on both sides of the

fitting will eliminate the air leakage. Eliminate use of the lock plate when

these seals are used.

These banjo bolts used to attach the oil line fittings will break or strip the

housing if overtorqued. Torque limit is 20 in/lbs. Stripped housings can be

restored using Helicoils.

The pump lever has a tab to contain the cable from the throttle lever. This tab

will break off if it is repeatedly bent..... open it just enough to remove the

cable and leave it alone.

The four hole pump used with H2B/C models has oil lines running to each

carburetor to lube the piston/cylinder. The case and cylinders of H2B/C motors

do not have oil passages to provide lubrication as earlier models do. Use of

three hole pumps with H2B/C cases or cylinders require modification to provide

oil to cylinders.

http://kawatriple.com/tips/casecyl_swaph2.htm

A detailed explanation of pump operation is available at

http://www.kawatriple.com/manuals/hseries/sec3.pdf page 43.

Oil Lines

Oil lines on some models have different diameters for different cylinders. This has no consequence whatsoever. The significant difference is with pre '74 and later lines. Pre '74 lines had "serviceable" check valves attached that could be easily disassembled where the later lines were fitted with check valves that are integral to the lines.

The H2B/C line (1 into 3) is unique and is prone to air leaks at joints. H2B/C

lines to the carbs do have check valves at carbs.

Check Valves

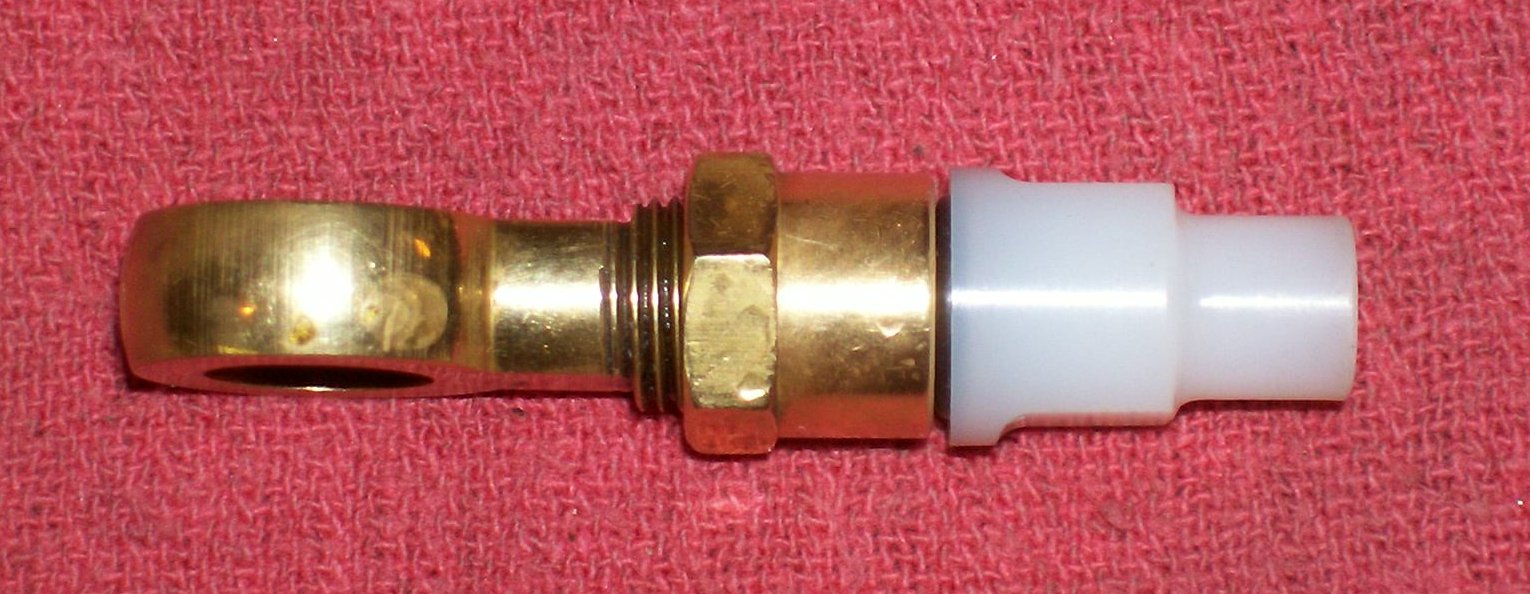

Check valves are used at the engine case

(and carb bowls on H2B/C) to regulate and prevent oil leaking into crankcase. It

also prevents crankcase pressure from overriding pump pressure. Early model

check valves had a crack pressure of 2.3 -2.8 psi. Later valves were set at 4.3

psi. The higher psi setting is preferable as it reduces the chance of leaking

valves.

Check valves are of the "serviceable" and "non-serviceable" varieties as

explained earlier. Very early ('69 model) H1's were fitted with a thicker body

valve (shown at bottom below) and different mating banjo bolt.

Check valves are the weak point in the oil system. With age they

can become corroded, clogged, and seats worn. A leaking check valve can seep

enough oil into the crankcase to cause piston hydrolock and bend a rod. A

blocked valve can reduce or eliminate oiling of cylinder.

New check valves are NLA from Kawasaki. The "serviceable" type check valves can

easily be disassembled, cleaned, and inspected. The "non serviceable" valves

require much more care and expertise to service. New springs and balls are

available via aftermarket. Care must be taken to orient the small end of the

spring against the ball.

Various techniques can be used to clean/remachine the ball seat

as may be required. Simple cleaning may or may not work depending on the amount

of corrosion/damage to the part.

Under no circumstances should compressed air be used on the check valve

assembly.

Testing

The simple way to test check valves is to blow/suck through the

valve. However, it can be difficult to ascertain results. Filling the lines with

oil and hanging them with the valve down can be an effective way to check for

leaks.

The most effective way to test them is with use of a gauge and small pump.